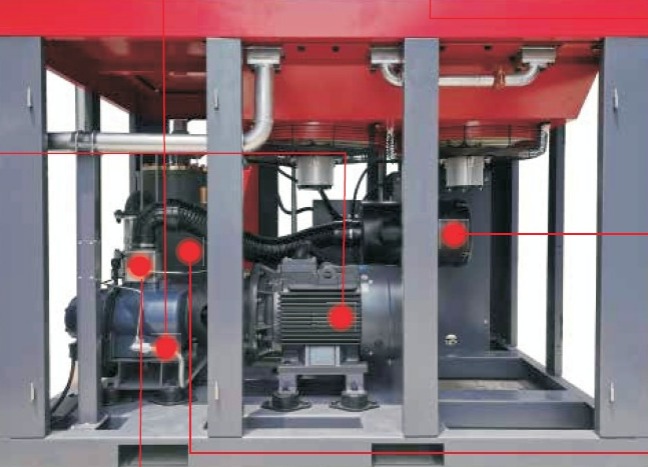

FIXED SPEED SCREW COMPRESSOR

COOLER

The heat exchanger uses high-quality raw materials and a unique internal channel design which increases the heat exchange area and effectively dissipates heat for the whole compressor. Inner wall treated with corrosion protection to increase service life.

FAN

Large fan design for excellent cooling and airflow. Controlled by a condenser/thermostat to maintain optimal working temperature and reduce thermal stress.

AIR-END

International top-level third-generation asymmetric screw rotor, high efficiency and low noise. Optimized flow channel design for improved energy efficiency and long life (bearing life up to 80,000–100,000 hours).

MOTOR

High-performance motors from well-known brands. Optional TEFC / IP54 / insulation grade F. Efficient, durable and with built-in protection for temperature and overload.

INTAKE VALVE

Core component to control air intake. Precisely controls inlet air volume for improved efficiency, lower power consumption and reduced operating cost.

CONTROLLER

PLC / microcontroller based control system with user-friendly interface. Provides automatic start/stop, fault protection, status display, and network/remote monitoring capability.

INVERTER

Optional VFD (inverter) for soft start, energy saving and smooth speed control. Reduces inrush current and enables variable flow to match demand.

OIL FILTER

High density filter media captures contaminants and protects lubrication system components. Improves oil life and performance of bearings & gears.

AIR FILTER

High dust-holding capacity element with low flow resistance; removes particulates and protects the air-end from contamination.

AIR-OIL SEPARATOR CORE

High-quality separation element and gas-liquid filter which ensures oil carryover is minimal and compressed air meets required cleanliness.